Newsletter/Blog post

Work Package 2

Janne Harjuhahto, Maillefer

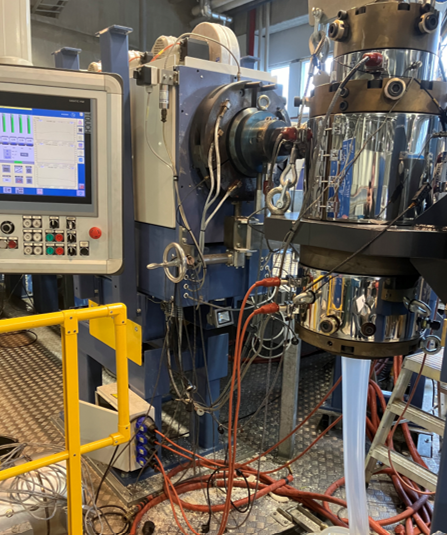

Maillefer’s R&D platform is helping set the benchmark for HVDC PP cables. Our role in the consortium is unique and powered by what defines us as a provider of extrusion solutions. We are leading the work package 2 titled Reliable-by-design manufacturing of novel HVDC cables in the NEWGEN project.

Overview of the tasks

At this point of the project, we have upgraded and assembled the lab line which serves to make the model cables composed of PP based compounds for outer partners in the consortium. The samples serve to compare against the classic XLPE type. The collective project lists several tasks split up amongst its members. Maillefer is assigned the following.

Task 2.1 – Cable extrusion equipment optimization

- Maillefer will produce the first model cables with current extrusion equipment and commercial thermoplastic blends for characterization using materials identified from prior phase. After this we have developed new extrusion equipment and solutions in order to improve HVDC cable properties when using PP based materials. Focus is in development of more efficient melting and mixing during extrusion process of thermoplastic in order to improve material homogeneity and electrical performance and development of new extrusion crosshead solutions for novel thermoplastic HVDC materials

Task 2.2 – Extrusion process optimization

- Maillefer will optimize the cable extrusion process conditions for new thermoplastic insulations to improve the properties and overall reliability of HVDC cables. The cable samples manufactured at wide range of processing conditions (extrusion speed, cooling rate, cooling pressure) will undergo characterization. Aiming to establish processing-morphology-property relationships for thermoplastic insulation to enable production of high-quality defect-free cables.

Task 2.3 – Space charge optimized HVDC cable prototypes and cable model “A” samples

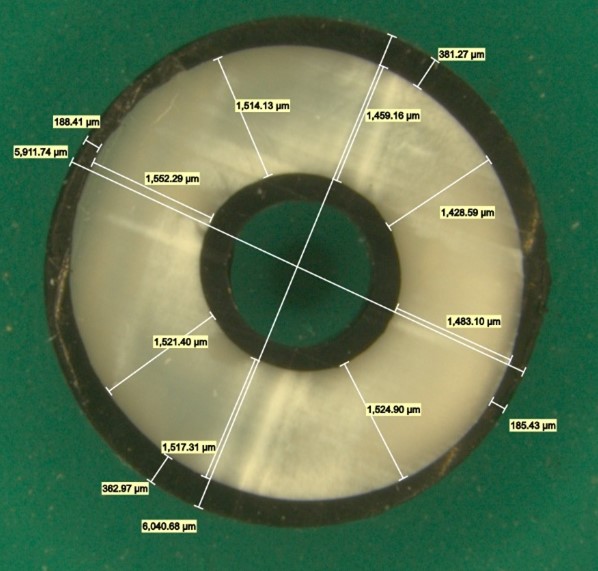

- Maillefer will produce multiple batches of two different size of cable samples using materials developed by other partners in the project. First, life-size HVDC cables prototypes with optimal industrial scale equipment and conditions. Second, smaller model cable “A” samples (as per Cigré 636) as seen in figure 1, 2 and 3. Both types of cables will be manufactured with novel and optimized HVDC materials developed by WP1.

Combining experience from the industry with academic research

In NEWGEN, manufacturing cable samples is important for full evaluation of the developed PP-based blends from work package 1. Realistic processing conditions for the extrusion and cooling phases will have an impact on the insulation material properties that would be difficult to estimate only from hot-pressed or extruded cast films. Compared to thin films, the model “A” cables have an order of magnitude thicker insulation while the HVDC prototypes have two orders of magnitude thicker insulation.

Much of the focus in tasks 2.1 and 2.2 is to understand the needed machinery and process modifications when transitioning from the industry standard XLPE to thermoplastic PP-based insulation materials in HVDC cables. Experience from the industry has revealed several areas for improvement, which were starting points for designing the first iteration of machinery improvements as shown in figure 4. The manufacturing of both types of cable samples using existing equipment, as well as some newly acquired equipment, will serve as a reference benchmark for the PP-based material. References will also be used to evaluate improvement needs and the effectiveness of future optimization in cable manufacturing equipment and processes.

In addition to new designs and equipment that have been manufactured, Maillefer has produced multiple batches of cables samples for other partners and work packages using the newly made equipment. Extrusion of cable samples has provided valuable insights for VTT and WP1 about the material suitability as well as samples for electrical characterization of the novel materials for WP1, WP3 and WP4. For example, a newly developed insulation extruder screw for PP based insulations has vastly improved the melt homogeneity visible in cable sample cross sections.

At the forefront

It is exciting to be very much involved in top academic research. Our R&D platform for PP cable exists; the know-how and experience with different materials is growing; and our network of expert partners with the capacity to collaborate with analytics and comparable data is expanding. The NEWGEN consortium is determinant in shaping the future of PP cable and green energy distribution.