On 23–24 October 2025, the NEWGEN partners gathered in Bologna, Italy, for the project’s M36 consortium meeting, hosted by Doble Engineering, marking the important milestone of three years in the project. Over the course of two days, the NEWGEN partners reviewed progress across the technical work packages WP1-WP4, including several important milestones and deliverables, and outlined the future plans to reach the objectives during the final period of the project.

In WP1 (Space charge mitigation in polymeric HVDC cable insulation), the focus was put on the optimized thermoplastic PP-based binary and ternary insulation blends and the effect of polymeric additives for space charge mitigation. Up-scaling to model “A” mini-cables and full-size HVDC cable prototypes has been reached, allowing more detailed testing in relevant cable designs.

In WP2 (Reliable-by-design manufacturing of HVDC cables), the focus was on new machinery and optimized processing for thermoplastic PP based HVDC cable manufacturing. For example, the new crosshead design specifically tailored for PP-based insulation is soon available for commercialization. Moreover, life cycle assessment (LCA), including social LCA (S-LCA) specifically focused on NEWGEN materials and processes were covered.

In WP3 (Novel pre-fault monitoring solutions for HVDC cables and accessories), a comprehensive definition of the detection and acquisition approach for partial discharges (PDs) under HVDC stresses has been reached, along with an extensive PD dataset gathered on various artificial defect containing samples. Moreover, proof-of-concept of a novel magneto-optic method for leakage current detection has been obtained, and the system will be tested in HV lab for model cables in the final period of the project.

Finally, in WP4 (Tools and models for reliable and resilient HVDC cable systems), the focus was on the development of life and reliability model of the HVDC cable, of HVDC cable accessories and of the whole HVDC cable system; with the models now available, the final focus will be put on verification of the model using accelerated lifetime tests (ALTs) on both state-of-the-art DC-XLPE and novel PP-based thermoplastic insulation materials within NEWGEN. This work is also closely connected with the assessment of the effects and resilience to faults of the HVDC cable connection in the AC network, aiming at strengthening the reliability and sustainability of future power grids.

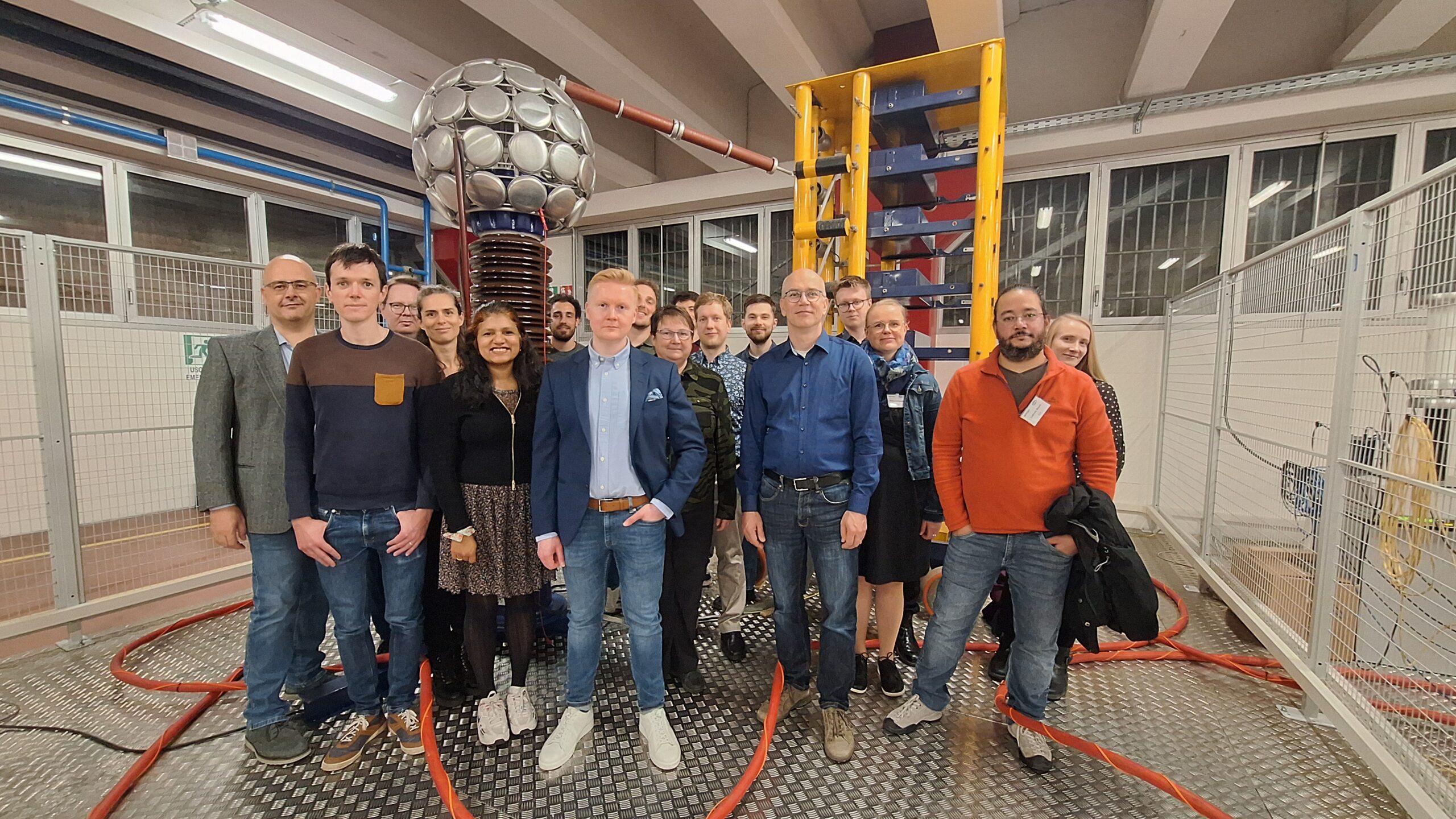

The meeting continued with a visit to Doble Engineering’s HV R&D Ciani Lab in Casalecchio di Reno, where partners had the opportunity to witness a live demonstration of the online condition monitoring prototype for HVDC systems, showcasing Doble’s progress in predictive diagnostics and reliability enhancement.

Building on insights from these discussions and three years of accomplishments, the NEWGEN consortium reaffirmed its commitment to continued collaboration to drive the sustainable development of advanced HVDC cable technologies and electrical systems.