Newsletter/Blog post

Work Package 1

Rafal Anyszka, University of Twente & Ilkka Rytöluoto, VTT

1. Introduction

High voltage direct current (HVDC) underground and submarine cables constitute an essential technology for the long-distance transmission of electrical power with minimal losses, thereby enabling European decarbonization and reaching climate neutrality by 2050 in accordance with the European Green Deal. In this context, the reliability of the HVDC cables and systems is crucial for the overall reliability and resilience of transmission grids, and expanding their utilization to higher power transmission capacity and ensuring their reliable operation over the expected lifetime of up to 40 years still requires new technological innovations.

The overall objective of NEWGEN is to develop and demonstrate new insulation materials, cable manufacturing solutions, online condition monitoring technologies, and comprehensive life and reliability modelling tools for next generation of extruded HVDC cables and cable systems. One of the more specific technical objectives within Work Package 1 of NEWGEN is to develop novel space charge mitigating additives which can remedy the issue with adverse accumulation of charge within the main insulation layer of extruded HVDC cables.

2. What is the issue with space charge, and what can we do about it?

Pre-mature ageing and damage to insulation material in HVDC cables can typically be caused by the accumulation of electric charges in specific areas within the material (space charge accumulation), which distorts the electric field distribution and can form conductive paths, ultimately leading to a dielectric breakdown and failure of the cable. Space charge accumulation is related to charge mobility within the insulation material, which depends on its trapping and detrapping properties. It is known from the literature that introducing functional chemical groups into the insulation material can tune the depth and density of the traps [1], thereby improving its insulation properties. However, often, the functional groups exhibit poor compatibility with the polyolefins used for the insulation manufacturing (crosslinked polyethylene (XLPE), polypropylene (PP)) due to the high polarity differences. This leads to agglomeration or leaching out of the chemical additives, which in turn results in worse electrical resistance of the insulation material. To overcome these issues, the NEWGEN project aims to chemically graft the functional groups directly onto the polyolefin polymeric chains to immobilise them in the insulation matrix and prevent them from agglomeration or leaching out.

3. Preliminary results on the effect of chemical modification of PP on its dielectric properties

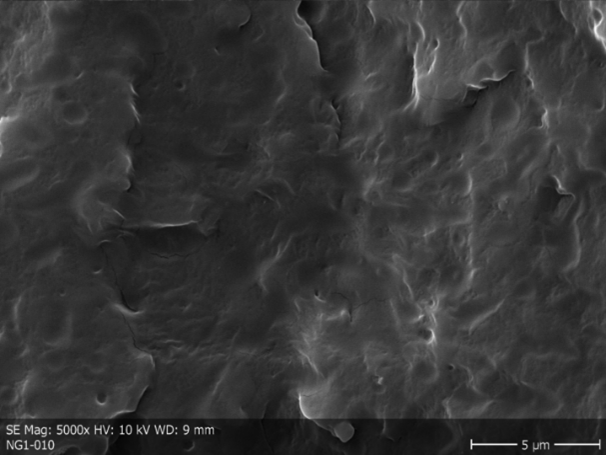

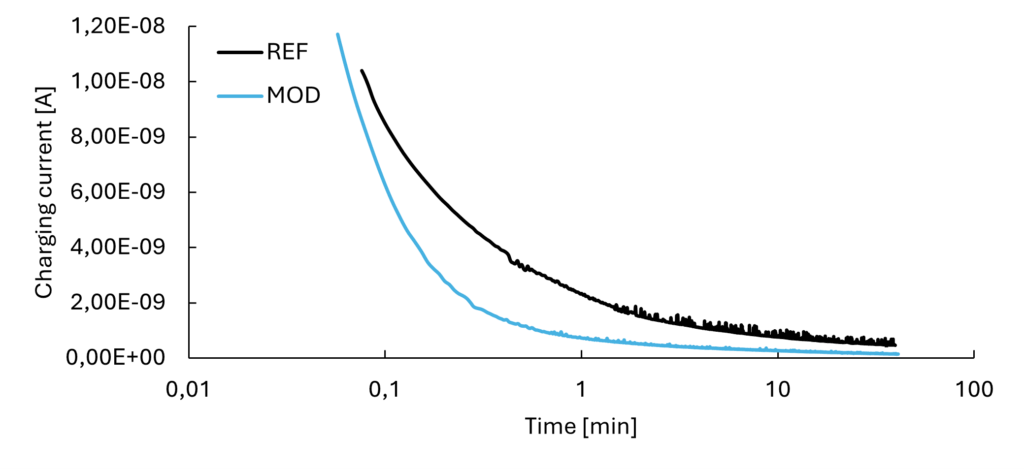

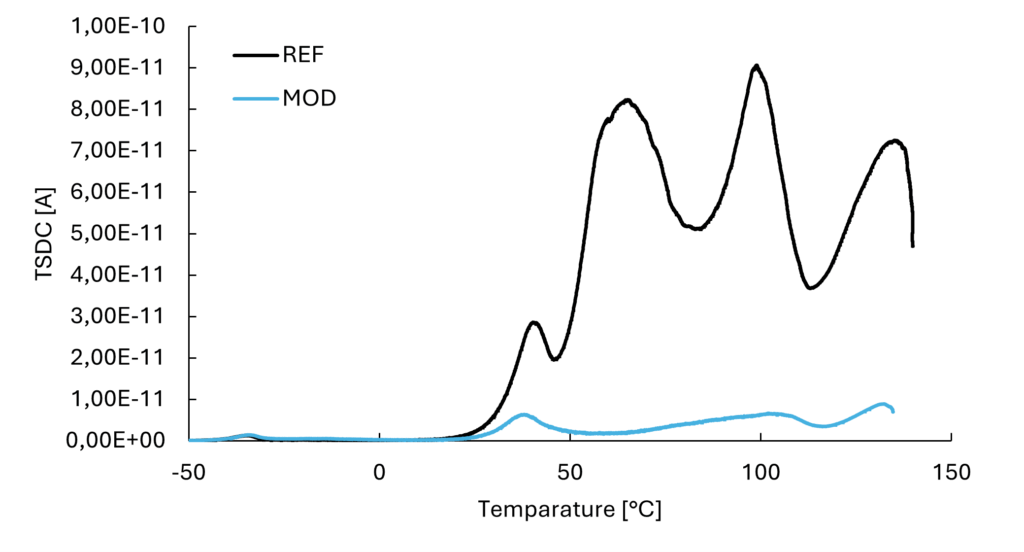

To demonstrate the effect of chemical modification on the properties of PP, we prepared a reference sample consisting of unmodified PP (REF) and a blend of unmodified and modified PP containing 2.5% of the modified PP (MOD). To investigate the morphological effects of PP blending, scanning electron microscopy (SEM) pictures were taken (Figure 1). The influence of the PP modification on the dielectric properties of the insulation materials was studied by the thermally stimulated depolarization current (TSDC) technique, recording the material charging characteristic (Figure 2) and depolarization current (Figure 3).

SEM analysis revealed that the blend of modified and unmodified PP (Figure 1b) exhibits very homogeneous micromorphology, similar to the reference unmodified PP (Figure 1a). This is most likely caused by high compatibility between the two PP grades, which have predominantly the same chemical structure.

Figure 2. Charging current of the reference (REF) and modified (MOD) PP.

Figure 3. TSDC results of the reference (REF) and modified (MOD) PP.

Chemical modification of PP resulted in a significant modification of charge trapping and reduction of total accumulated charge, as shown by the TSDC results (Figure 3). Also, the charging current stabilizes much faster at a lower value for the modified sample in comparison to the unmodified PP (Figure 2). This is in line with the TSDC results, indicating less space charge accumulation since the saturation in the charging current is achieved much faster.

4. Conclusions and outlook

Chemical modification of the PP chain results in a significant alteration of the dielectric properties of PP insulation blends by modifying the depth and density of charge trapping sites. A small yield of modification allows blending the modified PP with unmodified PP with good compatibility, obtaining homogeneous micromorphology of the blend.

The chemical additives developed in NEWGEN can pave the way for widely applicable solution for eliminating space charge accumulation in several different thermoplastic PP-based and XLPE-insulation materials, thereby having an impact on the whole extruded HVDC cable market.

References:

[1] He, Xiaozhen, et al. “Combining good dispersion with tailored charge trapping in nanodielectrics by hybrid functionalization of silica.” e-Polymers 21.1 (2021): 897-909.